Customized Solution

HKH technology is a series of high-pressure, high-temperature, and high-speed reaction kettles that utilize a vessel-in-vessel design to induce high-speed molecular movement. By utilizing high-speed shearing and emulsification, raw materials can be refined into smaller molecules and used to produce high-quality gels. The vessel-in-vessel design is made of special steel with high strength, rigidity, ductility, and plastic deformation ability.

The HKH technology is a necessary process for producing high-quality gels. It increases the refinement of molecules, making the products smoother and more easily absorbed by the skin. Additionally, the ves-sel's high-speed shearing can significantly reduce the likelihood of allergic reactions, making it a safer option for consumers.

By using HKH technology, the semi-finished products can be directly pressed into the large reaction kettle without going through a decompression or cooling process, saving time and increasing efficiency. The vessel-in-vessel design can reach a speed of 30,000 revolutions per minute, allowing it to quickly and effectively refine biological cell walls. This makes the components easier for the body and skin to absorb, resulting in a more comfortable user experience.

![$_output_data_['title']](https://www.pingchuangmed.com/data/watermark/20230502/6451188700938.png)

1. Develop products within three hours and increase production capacity by 10 times to meet the requirements of large orders.

2. Rotate at 30,000 revolutions per minute, break through barriers at high speed, refine molecules, and reduce allergy rates by more than ten times.

3. Shorten the time by 10 times compared to traditional processes.

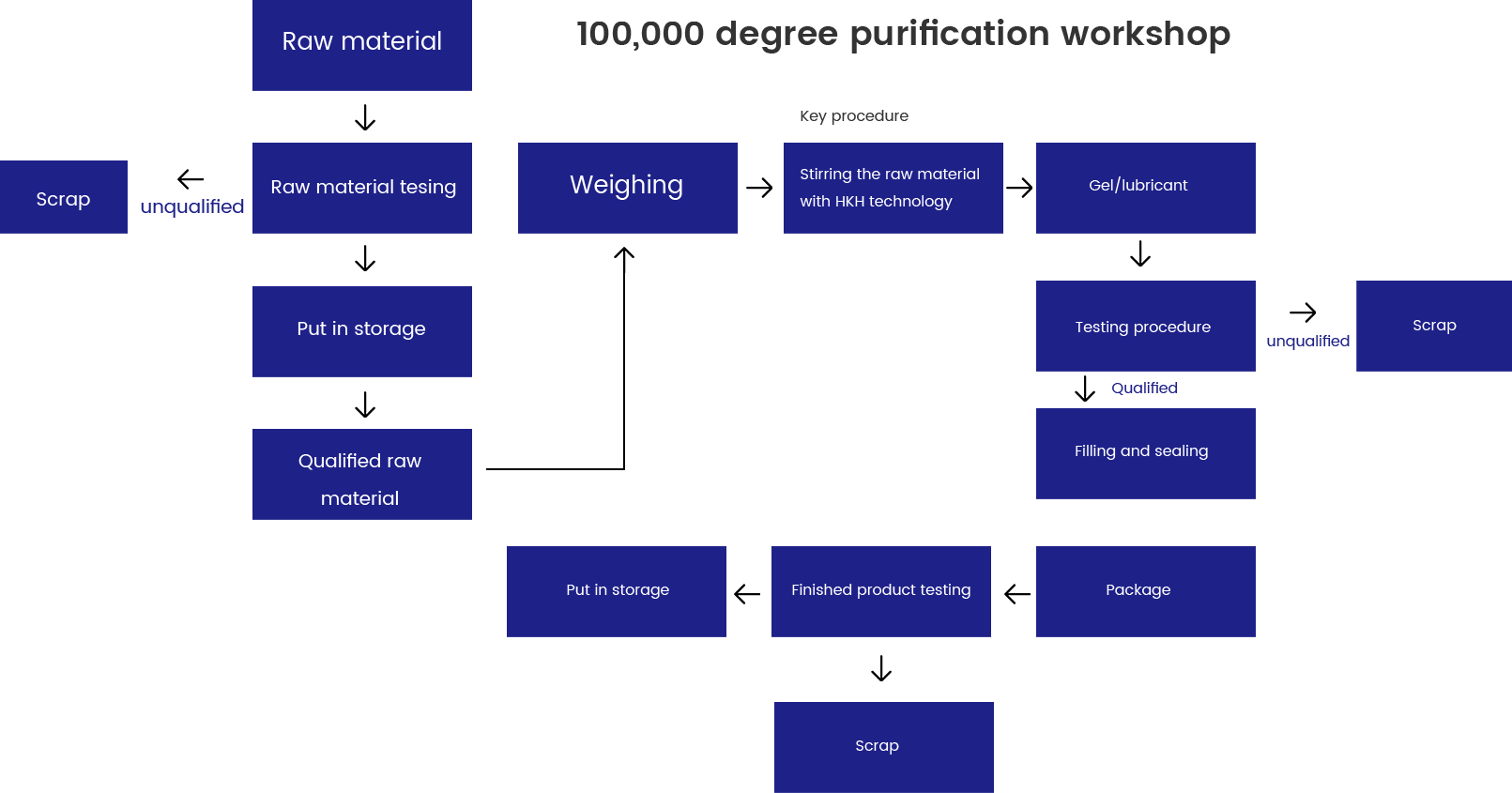

High-efficent producing process

High-efficent producing process